Katup Bola Welded Tekanan Dhuwur kanggo Minyak & Gas

BAL702

Deskripsi Produk

IFLOW katup bal sing dilas kanthi tekanan dhuwur kanggo aplikasi lepas pantai minangka solusi paling apik kanggo industri minyak lan gas. Digawe nggunakake teknik tliti lan teknologi canggih, katup kasebut dirancang kanggo tahan kahanan sing ekstrem lan menehi kinerja sing ora ana tandhingane ing lingkungan lepas pantai. Dibangun kanthi bahan kanthi kekuatan dhuwur lan awak sing dilas kanthi lengkap kanggo daya tahan lan linuwih sing luar biasa, saengga cocog kanggo operasi lepas pantai.

Katup kasebut dilengkapi mekanisme sealing canggih sing njamin penutupan sing ketat lan kebocoran minimal, saéngga nambah keamanan lan perlindungan lingkungan instalasi lepas pantai. Desain kasar lan kapabilitas tekanan dhuwur ndadekake cocok kanggo aplikasi kritis, nyedhiyakake kontrol aliran sing lancar lan kinerja sing optimal ing kahanan tekanan dhuwur. Konstruksi sing dilas kanthi lengkap ngilangi titik bocor potensial, menehi katentreman atine lan njamin integritas sistem minyak lan gas lepas pantai.

Katup bal sing dilas kanthi tekanan dhuwur IFLOW dirancang kanggo nyukupi standar industri lan syarat peraturan, njamin kepatuhan lan linuwih ing operasi lepas pantai. Desain kompak lan fitur instalasi efisien ndadekake solusi biaya-efektif lan kurang pangopènan kanggo instalasi lepas pantai. Pilih katup bal sing dilas kanthi tekanan dhuwur IFLOW kanggo aplikasi lepas pantai lan nemu kualitas unggul, daya tahan lan kinerja ing lingkungan lepas pantai sing paling nuntut.

Fitur

Ringkesan produk

Range bisa direkayasa supaya cocog karo aplikasi sampeyan, kanthi konstruksi awak, materi, lan fitur tambahan sing dioptimalake kanggo nyukupi kabutuhan proses sampeyan. Kanthi sertifikasi ISO 9023, kita nggunakake cara sing sistematis kanggo njamin kualitas sing dhuwur, sampeyan bisa yakin keandalan lan kinerja sealing sing luar biasa sajrone umur desain aset sampeyan.

Syarat Teknis

· Tekanan Kerja: PN20

· Suhu kerja: -10 ℃ ~ 170 ℃

· MEDIUM KERJA: Banyu, Minyak lan Uap

Spesifikasi

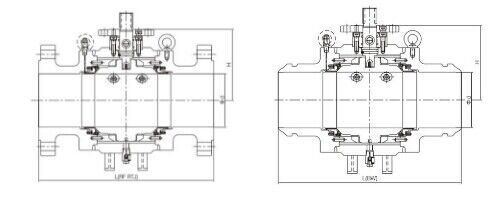

Produk wireframe

Data ukuran

Spesifikasi

| Diameter nominal (ing) | NPS6-40 | ||||||

| Tekanan nominal (Mpa) | Kelas 150-Kelas 900 | ||||||

| NO | NAMA BAGIAN | BAJA KARBON | STAINESS STELL | ||||

| Bahan bagean | 1 | awak | ASTMA 105 | ASMA 182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L |

| 2 | Packing anti api | Grafit | |||||

| 3 | Kursi | PTFE / NYLON / PEEK / PPL | |||||

| 4 | Ring kursi | ASTM A105.ENP | ASMA 182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L | |

| 5 | O-ring | VITON | |||||

| 6 | Spring | 17-7PH | |||||

| 7 | Bonnet | ASTMA 105 | ASMA 182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L | |

| 8 | Katup injeksi sealant | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | |

| 9 | Priksa katup | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | |

| 10 | bal | ASTM A105.ENP | ASMA 182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L | |

| 11 | Gasket dorong | PTFE | |||||

| 12 | Bantalan geser | Logam + PTFE | Logam + PTFE | Logam + PTFE | Logam + PTFE | Logam + PTFE | |

| 13 | Pin | ANSI 1035 | ANSI 1035 | ANSI 1035 | ANSI 1035 | ANSI 1035 | |

| 14 | Wadhah bantalan | ASTM A105.ENP | ASMA 182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L | |

| 15 | Kelenjar segel | ASTM A105.ENP | ASMA 182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L | |

| 16 | Bantalan dorong | PTFE | |||||

| 17 | Batang | ASTM A 182 F6a | ASTM A182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L | |

| 18 | Tombol flat | ANSI 1045 | ANSI 1045 | ANSI 1045 | ANSI 1045 | ANSI 1045 | |

| 19 | Bantalan dorong | PTFE | |||||

| 20 | Gasket anti geni | SST + Grafit | |||||

| 21 | Plat sambungan | ASTMA 105 | ASMA 182 304 | ASMA 182 316 | ASTMA182 304L | ASTM A182 316L | |

| 22 | Sekrup tutup kepala soket | A193 B7M | A320 B8 | A320 B8M | A320 B8 | A320 B8M | |

| 23 | Packing | Grafit | |||||

| 24 | Packing kelenjar | ASTM A 182 F6a | ASTM A 182 F6a | ASTM A 182 F6a | ASTM A 182 F6a | ASTM A 182 F6a | |

| 25 | Katup anti-statis | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | |

| 26 | Katup release udara | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | |

| 27 | Katup drainase | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | bagean gabungan | |

| Ketentuan layanan Applicalbe | Media sing ditrapake | Uap banyu, lenga, gas, cair, gas, gas alam, lsp | Asam nitrat Asam asetat | Asam asetat | Oksidator kuwat | Urea | |

| Suhu aplikasi | 120 ℃ (PTFE) | ||||||

| Desain lan manufaktur | API 608, API6D | ||||||

| Ukuran pasuryan-kanggo pasuryan | ASME B16.10, API 6D, JIS B2002 | ||||||

| Jinis sambungan | Flange | ASME B16.5/ASME B16.47 | Bult welding | ASME B16.25 | |||

| Tes tekanan | API598. API6D | ||||||

| Mode transmisi | Transmisi manual, cacing lan cacing, pneumatik, listrik | ||||||

data ukuran (mm)

| Rating tekanan | Diameter nominal | d | Flange | Bult welding | H | Bobot (kg) | |||

| kelas | NPS | DN | L(RF) | L(RTJ) | L (BW) | WE | RF | ||

| 150 | 6″ | 150 | 150 | 394 | 406 | 457 | 225 | 185 | 220 |

| 8″ | 200 | 201 | 457 | 470 | 521 | 258 | 250 | 290 | |

| 10″ | 250 | 252 | 533 | 546 | 559 | 310 | 400 | 430 | |

| 12″ | 300 | 303 | 610 | 622 | 635 | 350 | 550 | 620 | |

| 14″ | 350 | 334 | 686 | 699 | 762 | 382 | 820 | 900 | |

| 16″ | 400 | 385 | 762 | 775 | 838 | 421 | 1100 | 1220 | |

| 18″ | 450 | 436 | 864 | 876 | 914 | 468 | 1400 | 1550 | |

| 20″ | 500 | 487 | 914 | 927 | 991 | 510 | 1750 | 1950 | |

| 24″ | 600 | 589 | 1067 | 1080 | 1143 | 592 | 2800 | 3050 | |

| 26″ | 650 | 633 | 1143 | / | 1245 | 635 | 2900 | 3250 | |

| 28″ | 700 | 684 | 1245 | / | 1346 | 675 | 3400 | 3700 | |

| 30″ | 750 | 735 | 1295 | / | 1387 | 723 | 4800 | 5300 | |

| 32″ | 800 | 779 | 1372 | / | 1524 | 751 | 5500 | 6000 | |

| 36″ | 900 | 874 | 1524 | / | 1727 | 858 | 7550 | 8370 | |

| 40″ | 1000 | 976 | 1753 | / | 1956 | 930 | 10290 | 11320 | |

| 300 | 6″ | 150 | 150 | 403 | 419 | 457 | 225 | 185 | 230 |

| 8″ | 200 | 201 | 502 | 518 | 521 | 258 | 250 | 300 | |

| 10″ | 250 | 252 | 568 | 584 | 559 | 310 | 400 | 460 | |

| 12″ | 300 | 303 | 648 | 664 | 635 | 350 | 550 | 670 | |

| 14″ | 350 | 334 | 762 | 778 | 762 | 382 | 820 | 1000 | |

| 16″ | 400 | 385 | 838 | 854 | 838 | 421 | 1100 | 1320 | |

| 18″ | 450 | 436 | 914 | 930 | 914 | 468 | 1400 | 1650 | |

| 20″ | 500 | 487 | 991 | 1010 | 991 | 510 | 1750 | 2000 | |

| 24″ | 600 | 589 | 1143 | 1165 | 1143 | 592 | 2800 | 2550 | |

| 26″ | 650 | 633 | 1245 | / | 1245 | 635 | 2900 | 3300 | |

| 28″ | 700 | 684 | 1346 | / | 1346 | 675 | 3400 | 3750 | |

| 30″ | 750 | 735 | 1397 | / | 1397 | 723 | 4800 | 5500 | |

| 32″ | 800 | 779 | 1524 | / | 1524 | 751 | 5500 | 6500 | |

| 36″ | 900 | 874 | 1727 | / | 1727 | 858 | 7550 | 8800 | |

| 40″ | 1000 | 976 | 1956 | / | 1956 | 930 | 10290 | 11900 | |

| Rating tekanan | Diameter nominal | d | Flange | Bult welding | Umum | Bobot (kg) | |||

| kelas | NPS | DN | L(RF) | L(RTJ) | L (BW) | H | WE | RF | |

| 600 | 6″ | 150 | 150 | 559 | 562 | 559 | 255 | 250 | 330 |

| 8″ | 200 | 201 | 660 | 664 | 660 | 290 | 340 | 450 | |

| 10″ | 250 | 252 | 787 | 791 | 787 | 320 | 570 | 710 | |

| 12″ | 300 | 303 | 838 | 841 | 838 | 380 | 580 | 1000 | |

| 14″ | 350 | 334 | 889 | 892 | 889 | 410 | 1100 | 1370 | |

| 16″ | 400 | 385 | 991 | 994 | 991 | 435 | 1350 | 1650 | |